- Home

- Products

- Spray Coating

- Vacuum Spray Coating Machine

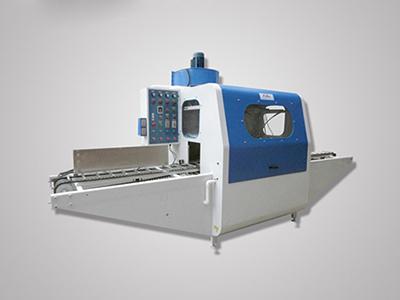

Vacuum Spray Coating Machine

Function

- The vacuum spray coating machine is a high-efficiency method of spraying all sides of the workpiece at one time, ideal for applying transparent base coating.

- The air in the application chamber is extracted by the vacuum pump to generate a paint mist. As the parts are conveyed through, the paint mist inside the chamber will uniformly attach to the surface.

- The sprayed coating film is thicker, which can avoid being worn and scratched in the subsequent sanding process and consequently reducing the rework rate.

- XMF vacuum spray coating machine is custom-tailored according to the shape of your workpieces. The size of feeding and discharging port can be custom designed and the width of the workpiece shall not exceed 400mm.

Application

The vacuum spray coating machine is perfect for the linear multi-surface coating of wood, synthetic board, plastic, glass and metal substrates, such as the door casing, skirting board and the photo frame casing.

Features

- The vacuum spray coater is appropriate for applying UV coatings to various irregular-shaped linear materials.

- The vacuum spray coating system is bended and made by the stainless-steel plates, which makes it wear- and corrosion resistant and ensures the long-term operation stability.

- Split design of application chamber and vacuum recycling box makes it easier to clean up and set up.

- The spray coating equipment is equipped with a high-power variable-frequency vacuum machine and an independent variable-frequency power transmission control mechanism to flexibly adjust the coating weight according to different production requirements.

- Paint heating filtering system, digital readout temperature control and automatic constant temperature heating device achieve a more uniform spray coating film.

- The curing machine consists of four groups of 5.6kw lamps and is equipped with a cooling fan to enhance the drying speed and improve the production efficiency.

Parameter

| Voltage | AC 380V three-phase four-wire |

| Frequency | 50HZ |

| Total power | 40KW |

| Working width | 0-200mm |

| Working thickness | 2-80mm |

| Minimum working length | 300mm |

| Feeding speed | 0-20m/min |

| Dimension | 8000mm×2000mm×1500mm |

Other Products

- +86-757-85688239

- Contact Us