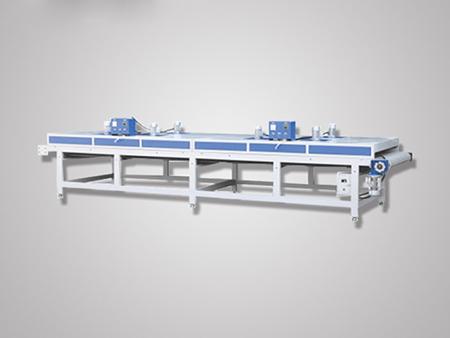

IR(Infra-Red) Drying

Function

- The IR (infra-red) drying machine is used for levelling or drying the coating on the substrate, which is realized by the heat from the quartz heating tube. The IR drying machine is ideal for levelling and drying various substrates with UV coating, water-based coating, PVC coating, NC coating, PU coating and etc.

- In order to make a thicker coating film smoother, the drying equipment will heat the coating to increase its ductility (fluidity). The leveled coating film will be smoother and more uniform.

- The IR drying machine is also suitable for drying coating with thinner, such as water-based coating and PVC coating, which have long natural drying time. The drying machine can heat the coating to speed up the thinner volatilization and shorten the drying time.

Application

IR drying machine is ideal for levelling and drying coatings on various substrates, such as wood, synthetic board, plastic, glass, metal and etc.

Features

- The levelling case has a double-layer thermal insulation device. Heat insulation foam is set inside to prevent heat loss.

- Digital readout temperature control system allows operators to easily regulate the temperature according to the production requirements (adjustable range: 0~200ºC). When the temperature reaches the preset temperature, the heating tube will automatically extinguish to save electricity cost.

- Optional devices upon request: hot air circulation system (create a more uniform temperature inside the machine case for better levelling performance); automatic dehumidification system (exhaust the vapor generated during solvent evaporation for better drying performance)

Parameter

| Voltage | AC 380V three-phase four-wire |

| Frequency | 50HZ |

| Total power | 15KW |

| Working width | 0-1320mm |

| Minimum working length | 300mm |

| Feeding speed | 0-20m/min |

| Feeding power | 1.5KW |

| Dimension | 6000mm×1600mm×1400mm |

- +86-757-85688239

- Contact Us