- Home

- Solution

Solution

XMF has dedicated ourselves to the production and customization of coating equipment since establishment in 2006. We are confident and are capable of providing you with a complete set of coating solution.

By drawing upon our extensive experience and production equipment, XMF can design an individual coating process for you on basis of your coating requirements. We can provide you with the specific adhesive for the coating machine you need. We have a complete supply chain of furniture production, which has offered us good supporting resources. Therefore, XMF has the capabilities of satisfying your one-stop purchasing requirements at competitive prices. We sincerely welcome you to visit our company and we will provide you various samples that our coating equipment has processed, including plane workpieces and irregular workpieces of wood, artificial board, glass, plastic, metal and other materials.

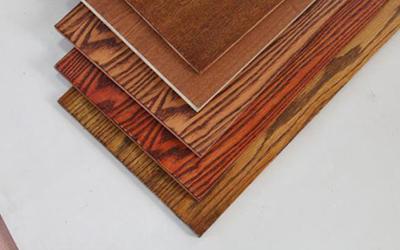

Applicable products: cupboard, wood doors, wood drawers, wood floors and etc.

Optimum productivity: 10m/min

Processes: embossing or distressing → dust removal → wood filling → coating curing → scuffing and sanding → coloring → wood grain printing → top coating → laminating

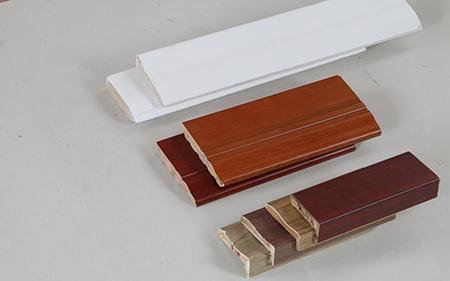

Applicable: skirting board, door casing, window casing, wooden handrail, window-blind, cue and etc

Optimum productivity: 5m/min

Processes: dust removal → wood filling → scuffing and sanding → coloring → top coating

The plate glasses feature smooth surfaces which can be directly applied with UV coatings or water-based coatings after cleaning and drying.

XMF is able to customize glass coating solutions by drawing upon over decade experience in glass coating equipment production. The maximum width of customized substrate is 2.5m. We can provide you with special paint or coating for glass finishing, such as high temperature flexible water-based paint or UV coating for glass decorative lighting, which has good flexibility after curing and allows to produce different shaped lampshade without crack.

The plastic surface is coated to obtain more patterns and colors for better decorative effects or to protect the product for longer service life.

XMF can provide plastic coating equipment to handle substrates of common plastic materials include fiber board, PVC, PS, acrylic. If you have other specific requirements, welcome to contact us for customization plastic coating solutions.

For copper or aluminum and other metal sheets, a coating film can increase its rust resistance and corrosion resistance to protect the substrates. XMF roll coating equipment is capable of finishing metal plate with thickness down to 0.13mm. An automatic cleaning device is also available to prevent the coating fluid contaminating the reverse side of the substrate.

High temperature water-based coating is often adopted for metal coating. The roll coating and spray coating equipment can effectively prevent the metal workpieces from crack or paint breaking during pressing, bending or cutting.

- UV coating has quick drying speed which results in the high finishing efficiency of 5-12m/min.

- Reusable UV coating to save paint.

- Semi-automatic or full-automatic UV coating line reduces labor cost and improves the product quality and stability under standardized management.

- The multi-purpose UV coating equipment is capable of completing base coat, top coat and coloring procedures, suitable for small batch production.

Different specialty finishing solution equipment can be customized according to customer’s needs, which are applicable to multifaceted, circular, square, irregular curved, fault workpieces, such as door casing, table leg, handrail and etc.

XMF multiple roller coater is specially designed to handle various specialty substrates. We install an elastic device on the applicator rolls which can stretch out or draw back when the substrate size differentiates to eliminate the coating errors and form a smooth coating film.

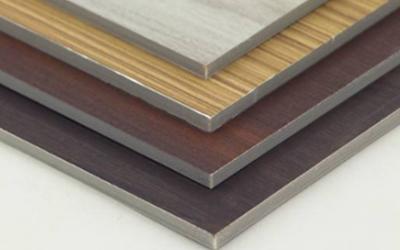

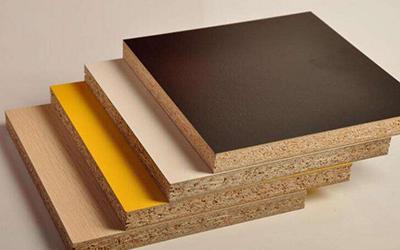

The synthetic board usually is the wood-based board, such as high density board and fiber board. It features smoother surface than natural wood and doesn’t need to fill the surface. Due to the economical benefit and no waste of wood resources, the synthetic board is widely used in daily life.

This board is used in office table, cabinet, curtain wall, floor, ceiling and other decorative materials. Outdoor or indoor specialty coating can be chosen according to the application.

- +86-757-85688239

- Contact Us